The third and final phase of one of the world’s greenest and most technologically advanced cargo facilities, the Long Beach Container Terminal at Middle Harbor, has been completed, Port of Long Beach officials announced Friday.

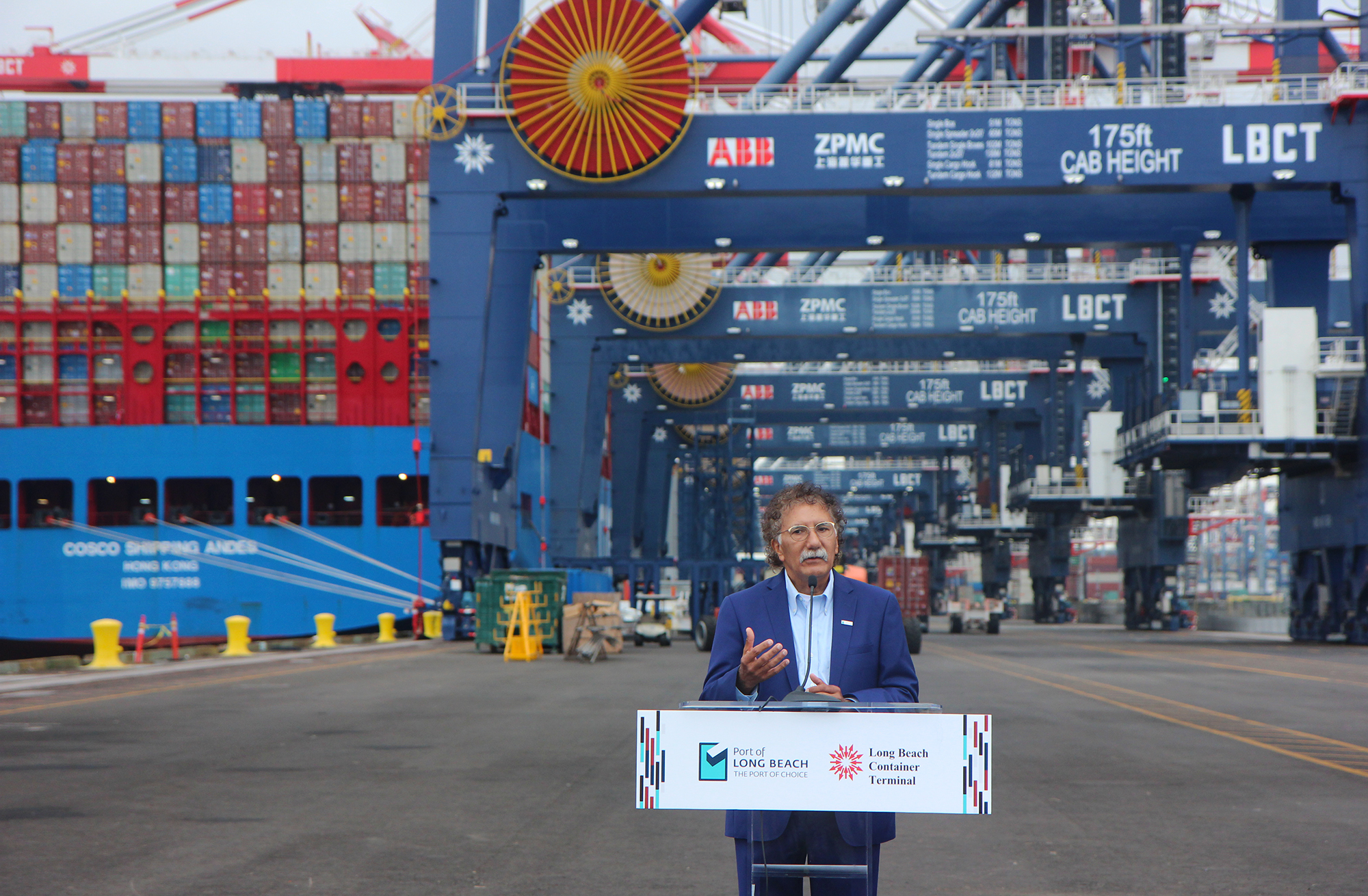

“The facility is one of the wonders of the maritime industry,” port Executive Director Mario Cordero said during a press conference. “Developing this terminal has been one of the biggest and most challenging infrastructure projects in our history.”

After years of planning, the first phase of construction on the 300-acre mega-terminal began in May 2011 and opened in spring 2016, while crews continued work on phases two and three. Phase two was completed in October 2017 and another three acres will be added in 2025 when the north gate expansion opens.

With a host of automated, electric and near-zero emission equipment, the terminal has the capacity to handle 3.3 million twenty-foot equivalent units—the standard container measurement—per year. This volume alone would rank LBCT as America’s sixth-busiest seaport, officials said.

“To give you some perspective, that is more than the entire Port of Oakland and almost as much as the combined ports of Seattle and Tacoma,” LBTC CEO Anthony Otto said during the press conference.

The project combined piers D and F into Pier E through the infill of 2.5 million cubic yards of dredged sediment from Newport Harbor, Marina Del Rey and Long Beach’s Colorado Lagoon and Alamitos Bay, according to port spokesman Eric Bradley. The terminal can accommodate three container ships at the same time utilizing 14 electric ship-to-shore gantry cranes along a 4,200-foot-long concrete wharf with four more on the way, port Senior Program Manager Monique Lebrun told the Business Journal.

All buildings at the terminal are LEED Gold certified, meaning they meet strict environmental standards, Lebrun said. All ships calling at the facility plug into shore power to tap into the port’s electrical grid to reduce emissions. LBCT also includes a large on-dock rail yard with over 70,000 linear feet of track, Lebrun added, which reduces the number of truck trips and further combats emissions at the port.

“This is a civil engineering marvel,” Lebrun said. “Each component is a huge project on its own.”

The final price tag for LBCT was $1.5 billion. The project initially was planned as an expansion of the two existing terminals and was budgeted for $750 million, Cordero told the Business Journal. However, when Hyundai relocated to the Port of Los Angeles, the project was reimagined into a single mega-terminal that utilizes state-of-the-art green technologies, which increased cost significantly, Cordero said.

For decades, the areas around the ports of Long Beach and LA have been plagued by some of the country’s worst air pollution, which has led to increased asthma for residents who live along major cargo corridors such as the 710 Freeway. The investment in creating LBCT is an indication that the port is taking action to address its environmental impact for the betterment of surrounding communities, Cordero said.

“LBCT is by far the cleanest container terminal on this planet,” Otto said. “We have proven our industry can [operate] in a more sustainable way—LBCT is operating at 90% less emissions than our competition.”

The terminal’s increased capacity has come in the nick of time, Otto said, noting the dozens of ships anchored off the coast awaiting to be offloaded. For over a year, the port has been handling a record amount of cargo due to increased e-commerce amid the pandemic. Coupled with the busy back-to-school and holiday stocking by retailers, high volumes are expected to continue.

The port generates about 51,000 jobs in the regional economy, including tens of thousands of International Longshore and Warehouse Union workers. In the past, the organization has fought automation at container terminals that would reduce the number of jobs for union members. While the technologies introduced at LBCT has impacted traditional longshore jobs, Otto said they have created newer, higher skilled jobs.

“We spent almost $9 million in training alone before we ever opened the doors of this facility,” Otto said. “That was our commitment to the workforce—retraining them so they can best handle the new technology. We can’t do this without the ILWU, we don’t want to. They are our workforce.”

Orient Overseas Container Line, a major Hong Kong-based shipper, in 2012 signed a 40-year lease to operate the new terminal through its subsidiary LBCT. In 2018, COSCO Shipping Holdings Co., a Chinese state-owned shipping line, acquired OOCL parent-company Orient Overseas (International) Limited.

Because COSCO is one of the largest shipping companies in the world by TEU volume, the Committee on Foreign Investment in the U.S. mandated the company divest at LBCT to avoid a monopoly. So in 2019, Australia-based asset management firm Macquarie Infrastructure and Real Assets acquired terminal operator LBCT and assumed the lease.

Editor’s note: This story has been updated with the correct spelling of Monique Lebrun’s last name.